The Internet of Things stands at an inflection point driven by a fundamental constraint: billions of IoT devices require continuous operation, yet batteries are expensive, require replacement, create environmental waste, and prevent deployment in remote or inaccessible locations. Historically, this created an impossible choice—either accept limited battery life and frequent maintenance or abandon IoT for inaccessible applications.

Recent breakthroughs in three complementary areas are transforming this constraint into opportunity. New low-power wireless technologies (LPWAN) extend battery life to 5-10+ years; dynamic power management techniques reduce consumption by up to 40%; and energy harvesting technologies enable truly battery-free operation in many applications. Collectively, these breakthroughs are democratizing IoT deployment, enabling sensors in locations previously inaccessible, and fundamentally shifting IoT economics.

This comprehensive analysis examines the technological breakthroughs enabling low-power IoT, exploring wireless protocols, power management strategies, and energy harvesting approaches that are reshaping the industry.

The Battery Crisis: Why Low Power Matters

The scale of IoT device deployment creates an environmental crisis. With 21 billion IoT devices online in 2025 and projections exceeding 40 billion by 2030, battery consumption is enormous. Research by the EU-funded EnABLES project projects that 78 million batteries will be discarded daily by 2025 due to battery replacement in IoT devices. This represents not only environmental waste but also operational burden—maintaining billions of devices with annual battery replacement cycles is economically and logistically unsustainable.

Traditional battery-powered IoT devices operate on 2-3 year lifecycles—acceptable for consumer devices frequently replaced anyway, but unacceptable for infrastructure sensors that should operate for a decade or more. A temperature sensor monitoring a water treatment facility, deployed in 2020 requiring replacement every 3 years, would require 3-4 replacement cycles over a reasonable 10-year device lifecycle, with associated maintenance costs, service disruptions, and waste.

Low-power breakthroughs enable devices operating 5-10+ years on single batteries, reducing replacement frequency by 3-5x, and enable truly autonomous operation through energy harvesting, eliminating batteries entirely.

LPWAN Protocols: The Foundation of Extended Battery Life

Traditional wireless technologies—Wi-Fi, Bluetooth, 4G cellular—prioritize throughput and responsiveness, consuming substantial power. IoT sensors transmitting small amounts of data infrequently don’t require high bandwidth; they require the opposite—ultra-low power consumption, wide coverage, and exceptional reliability.

Low-Power Wide-Area Network (LPWAN) technologies directly address these needs, optimizing for minimal power consumption while maintaining kilometer-scale coverage.

LoRaWAN represents perhaps the most successful LPWAN implementation, achieving ultra-low power through multiple innovations: spread-spectrum modulation allowing reception of weak signals with minimal amplifier power; efficient packet structure minimizing transmission time; and adaptive data rate technology that adjusts transmission power based on link quality. The result: LoRaWAN devices achieve battery life of 5-10+ years with typical deployment profiles, with some applications exceeding 10 years on a single battery.

LoRaWAN operates in unlicensed spectrum (868 MHz EU, 915 MHz US), enabling either public network deployments (through network operators) or private network deployment through organizations’ own gateway infrastructure. This flexibility appeals to enterprises wanting network control without carrier dependence.

NB-IoT (Narrowband IoT) takes the opposite approach—leveraging existing licensed cellular infrastructure operated by mobile carriers. Rather than deploying separate infrastructure, NB-IoT devices connect through carrier 4G networks optimized for IoT. This eliminates gateway deployment complexity but creates dependency on carrier network availability and incurs per-device SIM fees.

NB-IoT achieves remarkable coverage penetration—particularly in urban environments and indoors. Due to narrowband approach, signals penetrate building walls, basements, and underground areas far better than broadband technologies. Battery life reaches 3-5 years, shorter than LoRaWAN but competitive with traditional cellular IoT.

LTE-M (LTE for Machines) bridges LoRaWAN and NB-IoT, providing higher data rates (supporting firmware updates and voice) while maintaining low power. LTE-M enables device mobility (asset tracking on moving vehicles), a capability neither LoRaWAN nor NB-IoT supports. Battery life reaches 2-4 years, reflecting higher power consumption enabling advanced functionality.

Selection between these protocols reflects specific application requirements:

- LoRaWAN: Maximum battery life (5-10+ years), private network option, lowest operational cost

- NB-IoT: Exceptional coverage penetration, no gateway deployment, carrier support globally

- LTE-M: Real-time capability, mobility support, firmware updates, highest data rates

Hardware Innovation: Power Per Watt Revolution

Beyond protocol selection, chip-level innovations are dramatically reducing power consumption. Chipmakers are redesigning processors specifically for IoT, achieving remarkable efficiency improvements:

New chip designs deliver more computing power while consuming minimal energy—crucial for battery-powered sensors. Ultra-low-power processors now integrate multiple functions (CPU, radio, security accelerators, AI engines) into single packages, reducing component count and minimizing idle leakage current.

Semtech’s HL7900 5G LPWA module exemplifies these advances: cutting current consumption by up to 80% versus previous generation modules (HL78™ series), extending device battery life by up to four times. This is not incremental improvement—it represents generational advancement enabling deployment scenarios previously impossible.

Smaller transistor geometries (12nm, 7nm fabrication) reduce leakage current and improve performance-per-watt. Specialized low-power modes enable devices to sleep at microsecond latencies, awakening only when needed. Integrated energy harvesting support enables hybrid battery-solar approaches.

Real-world analysis demonstrates these principles: research analyzing ESP32 microcontroller power consumption across different configurations reveals clock frequency is the dominant factor—operating at 40 MHz consumes far less than 240 MHz operation, with voltage selection providing secondary optimization. Reducing frequency from 240 MHz to 40 MHz achieves 80-90% power consumption reduction, dramatic enough to extend battery life from months to years.

Power Management: Intelligent Energy Conservation

Dynamic Voltage and Frequency Scaling (DVFS) represents a fundamental power management technique enabling devices to adapt power consumption to workload requirements. Rather than running processors at fixed clock speeds regardless of load, DVFS scales both voltage and frequency based on computational demands.

The physics underlying DVFS is elegant: P=C×V2×FP=C×V2×F, where power consumption (P) is proportional to the square of supply voltage (V) and linearly proportional to frequency (F). Reducing voltage from 3.3V to 2.5V reduces power by approximately 43%; further reducing frequency amplifies savings. The cubic relationship between supply voltage and power makes voltage reduction extraordinarily effective—doubling performance reductions can achieve 8x power reduction.

Practical DVFS implementations monitor processor utilization and dynamically adjust parameters:

- High load: Maximize frequency and voltage for performance

- Medium load: Moderate frequency and voltage balancing performance and energy

- Low load: Minimize frequency and voltage, reducing power consumption to milliwatts or microwatts

- Idle: Disable non-essential circuits, enabling sleep modes consuming only leakage current

Real-world deployments demonstrate up to 40% energy savings using DVFS without compromising functionality. For battery-powered IoT devices operating intermittently (transmitting 1% of the time, sleeping 99%), DVFS combined with aggressive sleep modes is the foundation enabling extended battery life.

Advanced adaptive DVFS uses machine learning algorithms predicting workload patterns, preemptively scaling parameters to optimize future power consumption. Bayesian classifiers predict processor performance states; reinforcement learning algorithms optimize power allocation across heterogeneous components.

Energy Harvesting: The Future is Battery-Free

While LPWAN and power management extend battery life substantially, energy harvesting removes the battery entirely, enabling true autonomous operation. A device powered by ambient energy sources requires no battery replacement, no maintenance, and can operate indefinitely in environments with sufficient ambient energy.

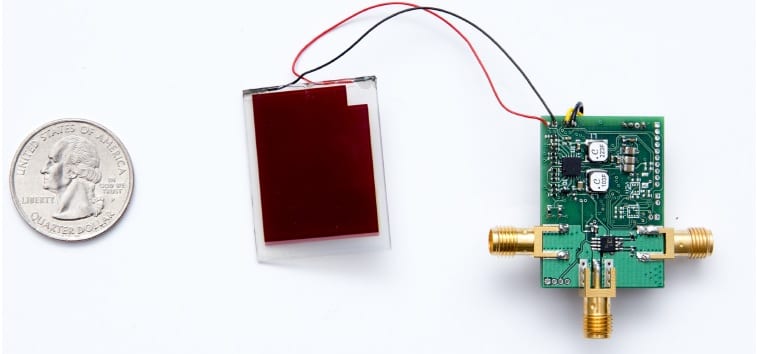

Solar/Photovoltaic Harvesting represents the most mature and highest-power-density approach. Outdoor sensors harvesting direct sunlight extract 5-100+ mW continuously; even indoor sensors harvesting artificial light extract 0.1-1 mW—sufficient to power low-duty-cycle IoT sensors. Solar efficiency has improved dramatically: new indoor photovoltaic cells optimized for artificial light spectra achieve 15-25% practical efficiency, while emerging perovskite materials approach 50% in laboratory conditions.

Applications are proliferating: smart agriculture deploys solar-powered soil moisture and nutrient sensors in remote fields; environmental monitoring stations harvest solar energy at dispersed locations; smart metering benefits from solar-powered sensors eliminating battery replacement for utility companies.

Thermoelectric Energy Harvesting exploits temperature differentials, converting heat flows into electricity through thermoelectric generators (TEGs). Industrial machinery—motors, compressors, heat exchangers—dissipates enormous heat, creating sustained temperature differentials enabling power generation. Manufacturing plants can harvest heat from machinery operating continuously, generating 0.1-1 mW continuously throughout operational periods.

Real-world deployments extract power from machinery heat to fuel condition monitoring sensors—vibration sensors detecting bearing wear, temperature sensors monitoring operating conditions—all powered by the very machines they monitor. This elegant approach eliminates batteries from industrial equipment while actually improving maintenance prediction.

Piezoelectric/Vibration Harvesting converts mechanical motion into electricity through piezoelectric elements experiencing strain during vibration. Manufacturing facilities vibrate constantly; machinery generates sustained high-frequency vibrations enabling power extraction. Vibrating machinery can power 0.5-5 mW harvesters; wearable devices harvesting human motion power 0.01-0.5 mW.

The challenge lies in frequency matching: piezoelectric harvesters operate most efficiently at specific resonant frequencies. A harvester designed for 50 Hz vibration generates minimal power at 100 Hz. Researchers are developing adaptive harvesters tuning themselves to ambient vibration frequencies, and nonlinear designs enabling broadband operation.

RF Energy Harvesting captures ambient radio-frequency signals—Wi-Fi, cellular networks, dedicated RF transmitters—converting them to electricity. While power levels are extremely low (typical ambient RF yields 0.0001-0.01 mW), this approach enables passive devices requiring no batteries whatsoever.

Qualcomm, Intel, Infineon, and other industry leaders have launched the Ambient IoT Alliance specifically to advance battery-free IoT powered entirely through RF harvesting from ambient wireless signals. This technology promises dramatic cost reductions—removing batteries eliminates approximately 30% of device cost; eliminating charging infrastructure and maintenance further reduces total cost of ownership.

Applications include retail inventory tags attached to individual items, tracking location and condition from warehouse through checkout without battery replacement; pharmaceutical cold-chain monitoring sensors ensuring vaccine and medication integrity during transportation; industrial equipment sensors predicting maintenance needs powered entirely by ambient RF.

Hybrid Energy Harvesting combines multiple sources—solar + vibration, solar + thermoelectric, vibration + RF—enabling robust operation in variable environments. A device in a manufacturing facility combines heat harvesting (from machinery), vibration harvesting (from equipment motion), and potentially solar (from facility skylights). The combined approach generates 5-100+ mW, sufficient to operate sophisticated sensors and wireless communication.

Research demonstrates hybrid approaches adding 11+ hours of operational time on average to IoT devices—dramatic enough to convert intermittent duty-cycle operation to near-continuous operation.

Power Management Electronics: The Unsung Hero

Energy harvesting is only as good as the electronics managing it. Power Management Integrated Circuits (PMICs) designed specifically for energy harvesting face unprecedented challenges:

- Ultra-low startup voltage: Solar cells generate ~0.5V in dim light; TEGs generate even lower voltages. Traditional PMICs requiring 1.2V startup voltage cannot harness this power. Advanced EH-PMICs start up at 0.1-0.3V, capturing every microwatt.

- Maximum Power Point Tracking (MPPT): Harvesters’ output impedance is highly nonlinear—optimal load resistance changes with environmental conditions (light level, vibration amplitude, temperature). MPPT algorithms continuously adjust impedance, maintaining operation at maximum efficiency.

- Multi-source management: Hybrid systems require simultaneously managing power from multiple sources with different characteristics, prioritizing sources, and maintaining stable system operation.

- Energy storage selection: Supercapacitors store energy efficiently with minimal voltage drop but discharge quickly; rechargeable batteries provide stable voltage but require careful charge management. Advanced PMICs intelligently switch between storage technologies, using supercapacitors for burst power and batteries for sustained operation.

Companies like e-peas develop specialized PMICs maximizing harvested energy—their technologies enable 15+ years of research optimized for energy harvesting-specific challenges. These PMICs represent the critical enabler between harvesters and sensors—without sophisticated power management, harvester output cannot be efficiently utilized.

The 78 Million Batteries Problem: Environmental Imperative

The EnABLES project’s stark finding—78 million batteries discarded daily by 2025 due to IoT device replacement—drives urgency. Each battery represents:

- Environmental cost from mining, manufacturing, and disposal

- Operational cost of replacement logistics and labor

- Maintenance burden on infrastructure systems

- Waste management infrastructure strain

The solution combines three strategies:

Extended battery life: Modern LPWAN devices achieve 5-10+ year battery life, reducing replacement frequency by 3-5x. At scale (billions of devices), this reduces annual battery waste by 65-80%.

Reduced energy consumption: DVFS, sleep modes, and efficient protocols reduce power consumption by 40-80%, proportionally extending battery life.

Energy harvesting: True autonomous operation eliminates batteries entirely for appropriate applications. Even hybrid approaches (battery + harvesting) reduce effective battery consumption, extending replacement intervals.

Real-World Application: Smart Buildings

Smart buildings exemplify how low-power breakthroughs enable deployment at scale. Building sensors—occupancy detectors, temperature/humidity monitors, light sensors, door/window contacts—were traditionally hard-wired with constant power. Smart buildings replacing hard-wiring with wireless sensors face a challenge: power consumption and maintenance cost.

Low-power IoT solutions: Deploy LoRaWAN sensors drawing 1-10 µW in sleep mode, 5-50 mW during transmission, transmitting occupancy changes 1-5 times daily. Batteries operate 5-7 years, far longer than device lifecycle. Installation cost decreases dramatically—no electrical conduit required, no electrician labor, simple sensor placement anywhere.

Energy harvesting enhancement: Adding small solar panels enables indefinite operation. Conference rooms receiving daylight harvesting 0.5-2 mW continuously eliminate battery requirement entirely. Even dimly lit hallways harvesting 0.1 mW extend battery life to 50+ years—effectively making devices permanently autonomous.

The result: buildings deploy thousands of wireless sensors monitoring comfort, occupancy, air quality, with minimal maintenance overhead. Combined with analytics, this enables 30-40% energy consumption reduction through occupancy-based HVAC optimization.

Future Directions: Ambient IoT at Massive Scale

By 2030, projections suggest 1 billion ambient IoT devices powered entirely through energy harvesting. This represents a paradigm shift: IoT transitions from “devices powered by batteries that require replacement” to “devices powered by ambient energy indefinitely.”

Key developments enabling this transition:

Standardization: The Ambient IoT Alliance is establishing standards for battery-free IoT, ensuring interoperability across manufacturers and enabling ecosystem development.

Emerging materials: Perovskite solar cells promising 50%+ efficiency; new thermoelectric materials with higher figures of merit; advanced piezoelectric materials with broader frequency response.

AI-enabled optimization: Machine learning algorithms dynamically optimize power harvesting and management as environmental conditions change, adapting to seasonal variations, daily lighting patterns, and equipment operation cycles.

Integration and miniaturization: Continued PMIC evolution embedding multiple functions—charging, storage management, power conversion, load monitoring—into single compact packages.

Low-power IoT represents one of the most consequential technology transitions of the coming decade. By combining LPWAN protocols extending battery life to 5-10+ years, power management techniques reducing consumption 40-80%, and energy harvesting enabling battery-free operation, the industry is transforming IoT from a technology requiring constant maintenance to autonomous systems operating indefinitely.

The environmental imperative is compelling: 78 million batteries discarded daily by 2025 demand alternatives. The economic opportunity is compelling: massive reduction in maintenance costs, elimination of battery supply chains, and enabling sensor deployment in previously inaccessible locations.

Organizations embracing low-power IoT today—selecting appropriate LPWAN protocols, implementing power management optimization, and evaluating energy harvesting opportunities—position themselves for dramatically reduced operational costs, environmental benefits, and superior system reliability compared to battery-dependent alternatives. The future of IoT is not more powerful batteries; it is smarter electronics consuming less power and harvesting ambient energy autonomously.